Komatsu Dump Truck Brakes

Making Komatsu truck brakes last

A major mining company was having severe wear on their truck brakes causing down time and expensive repairs. They tested cryogenically treated brake rotors vs. untreated rotors and achieved dramatic results. The issue was with the excessive wear and cracking on the service brake rotors and brake pads on the Komatsu 730E in their fleet and were trying to find a cost-effective solution.

The Experiment

The truck brakes on the 2000 horsepower Komatsu 730e trucks have a gross weight of 715,000 pounds to stop from speeds up to 35 mph. Each side on the front has a 46-inch diameter rotor operated by three calipers. Each side on the rear has two 25 inch rotors driven at armature speed. The rear rotor has one caliper.

In an attempt to explore a fix to the problem, Our Cryogenically treated Komatsu truck brake rotors (provided by the mining company) were installed to the left-hand side of one of the trucks. Untreated Komatsu rotors were used on the right hand side to act as a control.

The Results

After one month the truck brakes were inspected. The treated rotor had no cracks and the untreated one had severe cracking to the surface. The pads on the treated rotor had worn 1.5 mm versus 7 mm on the pads on the untreated rotor. So at this point maintenance had replaced the right hand rotors .

The next inspection recorded was at 5 months. The right-hand side had already had its second rotor fitted. This second rotor was now cracked far more severely than the original. The treated rotor was still on. Some cracking had developed but these cracks were quite minor in size when compared to the untreated side.

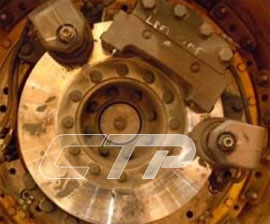

Treated Rotor After 5 Months of Use!

Treated Rotor After 5 Months / Zoom

Treated Rotor After 5 Months of Use

Untreated After 2 Months of Use

Utreated rotors After 2 Months Zoomed in

Utreated rotors After 2 Months

The Company’s Report

“It is obvious to date that the treated rotor will outlast at least 3 conventional rotors and in fact will be monitored weekly just to see how far it will go before it needs to be discarded. The deep and open cracking of the conventional rotor in such a short time will affect the pad wear quite considerably given the speed at which these rotors rotate in service which in this instance is 27:1 compared to the tire rotation.”

Contact Controlled Thermal Processing Today

If you run a business fleet or construction equipment, you’re always looking for a way to improve your bottom line. With deep cryogenic processing of brake rotors and crown wheels, you can dramatically reduce your maintenance and replacement costs. To get an estimate for treating your automotive parts with cryogenic processing, contact the specialists at CTP online