WPC treatment®

Micro Dimpling

Why WPC?

WPC improves friction wear characteristics by changing the surface

It can be used in a wide range of fields as a surface modification technology that greatly increases fatigue strength and function of mechanical parts.

Industrial

Racing

Pharmaceutical

Reducing Friction +

In addition to the dimpling, in cases where it’s needed, DFL (dry film lubrication) are then shot onto the surface to form a lubrication layer.

In combination with our WPC treatment®, has a long-term low friction effect that lasts.

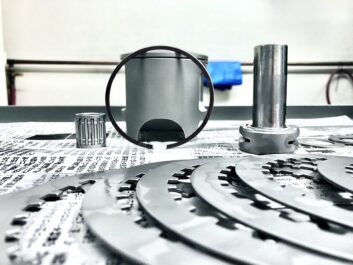

Use Case

In 1999, an OEM car manufacturer under a collaborative agreement applied our micro dimple treatment with dry film lubrication to the top ring of their piston ring and skirt.

The dry film lubrication is embedded at 4µm below the 11µm micro dimple surface texture and after 100 hours endurance testing the MoS was found even after surface wear. It was observed that the effect of the MoS was maintained.

This led to a friction reduction on the piston which contributed significantly to the fuel economy of the engine. Link to research

Improved Oil Film Retention

Increased Fatigue Strength

Improved Wear Resistance

50x ZOOM

WPC: Lubrication Transformation

Dimples Revolution

Typical Linear grooves that are formed on a machined product surface or flat honed surfaces are transformed into micro-dimples by ultra-fine media during the WPC Process.

These dimples then act as oil reservoirs.

This helps to keep the surface lubricated especially under elevated rotational and linear speeds.

Mastering Microscopic Texture

Fine Control of Surface Roughness

Since WPC processing uses very fine particles, it will create fine and uniform depressions on the surface. This is how micro dimples are formed. WPC treatment eliminates machining marks and creates micro dimples with sub-micron depth.