What is Cryogenic Processing

The heat treatment of metals is commonly understood as the addition of heat to metals, thereby increasing the temperature in a controlled manner, to bring about desirable changes in the crystal structure. The final step in heat treatment procedures is cooling to room temperature.

Cryogenic Processing, in contrast, takes advantage of desirable changes to crystal structure if cooling is extended to very low, sub atmospheric temperatures. Very low temperature, meaning cryogenic temperatures, is defined as temperatures below -150 °C. (-238 °F.) In the same way extremely hot temps cause changes in metal, extremely cold temperatures create changes. Except the changes at Cryogenic temperatures taking place are, finishing and perfecting the metals that was started by heat treatment.

Benefits of Cryogenic Processing

The benefits for cryogenic processing to material properties are numerous and significant. A partial list includes:

- Enhanced abrasion resistance

- Improved fatigue strength

- Better corrosion resistance

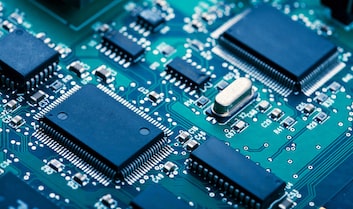

- Improved electrical and thermal conductivity

- Reduced internal stress

- Improved dimensional stability

- Better surf ace finish (for materials polished after deep cryogenic treatment)

Additional benefits are being revealed every day. Many of the above improvements are found not only in metals, but in many crystalline and semi crystalline (polymer) materials.

Industries That Use Cryogenic Processing

Industries that employ cryogenic processing because of the economies or performance benefits that it offers include:

- Manufacturing concerns that use cutting tools

- Producers of metal optical components

- Manufacturers of cutting and welding tools for industrial and consumer products

- Earth moving and mining industries

- Producers of injection molded products

- Performance and competition automotive components

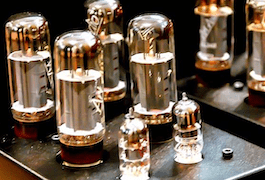

- High fidelity audio equipment producers

- Agricultural and logging products manufacturers

- Aerospace and military

Lasting Results

Lasting Results  Enhanced Resistance

Enhanced Resistance Industry Leaders

Industry Leaders