Cryogenically Treated Brake Rotors

At Controlled Thermal Processing, we’ve taken what we learned about cryogenically treated brake rotors in a racing environment and applied it to road vehicles. Today, we are proud to offer cryo treated rotors and pads to qualified fleets. Learn how deep cryogenic treatment of brakes can save hundreds of dollars per vehicle per year, and choose to protect your vehicle parts through our advanced cryogenic processing methods.

Curious about getting your brakes treated? Get a quote

The Benefits of Cryogenically Treated Brakes

- Reduced rotor wear

- Reduced rotor warping

- Reduced cracking

- Reduced pad wear

- More environmentally friendly

Many worn out rotors end up in landfills where they pollute the environment. Even if they are recycled, it takes energy to transport them, melt them, and recast them. When you work with Controlled Thermal Processing to cryogenically treat your brake rotors, it extends their life before they need to be replaced. Consider your impact on the environment and choose a greener method when you partner with CTP.

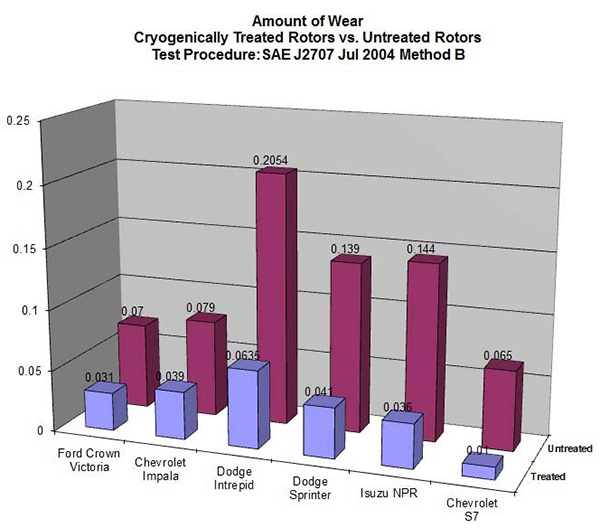

CTP has had both treated and untreated brakes tested by Greening Testing Laboratories and Link Laboratories according to SAE 2707 JUL 2004 METHOD B. Both these independent testing labs that are well known for their work with brakes. They found that brake rotors and pads lasted significantly longer after cryogenic treatment, with no significant change in braking effectiveness. In some cases cryogenically treated brakes have increased lifespans of up to 300% compared to untreated brakes.

Longer Lasting Brakes are Environmentally Friendly

In addition to a smaller carbon footprint, cryo treated brake pads also protect waterways and aquatic life, as they are less likely to shed metal along roadways and sewer systems. Brake pads contain copper which is often worn off and deposited along the roadway where it makes its way into the sewer systems and into rivers, lakes and oceans. Copper pollution is a major problem, especially along the coastlines where it does considerable damage to ocean life.

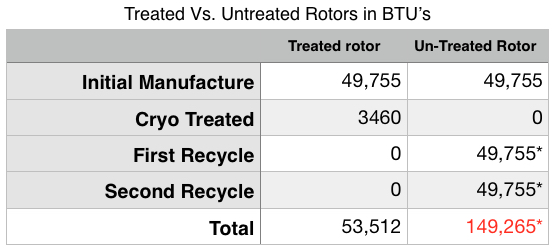

A cryogenically treated brake rotor lasts as long as 3 untreated rotors and uses almost 1/3 of the energy output to produce.

*Does not include transportation and machining energy use.

Recycle Used Brake Rotors

Cryogenically treating rotors results in brakes that last up to 300% longer before they have to be recycled. CTP highly encourages cryogenically treating brake rotors to reduce the costs of replacement and then to recycle them rather than disposing them in a landfill. Brake rotors are made of cast iron, which is easily recycled. Sending rotors to a landfill is not environmentally friendly, but even recycling has its costs.The mining and smelting of iron ore is energy intensive.

Curious about getting your brakes treated? Get a quote

Let’s take a look at the environmental results:

To recycle a rotor requires melting them down. A common rotor for a full size car weighs about 24 lbs. They just don’t melt a rotor, they melt a large batch of scrap metal, usually in a device called a copula. The energy use of a copula can hit up to 800 kilowatt hours per metric ton.

This calculates out to about 9 kilowatt hours per 24 lb rotor, which works out to about 31,000 BTU’s per rotor.

In addition to that there are other energy costs.

- Gates, runners and risers in the brake rotor mold require about 50% more metal than found in a brake rotor. It generates about 46,500 BTU to cast those brake rotors.

- During the melting process about 7% of material is lost due to reacting with the atmosphere and creating dross or iron oxide. An additional 3,255 BTU’s is used to process additional metal to make up the difference.

- To cast a new brake rotor involves about 49,755 BTU’s of energy used, not counting what it takes to get it to the recycling plant and the energy used to machine the resulting casting.

The bottom line is that every time a brake rotor is sent for processing creates large amounts of energy costs. Reducing that BTU usage by replacing brake rotors up to 3x less frequently is the best thing for the environment.

Deep Cryogenic Treatment Energy Usage

It takes about 8.2 liters of liquid nitrogen to process a rotor in our medium size machine. Air Liquide tells us that to make that amount of liquid nitrogen would take about 2460 BTU.

The heating cycle in the machine also takes about 1000 BTU Electrical usage per rotor in the machine. Now the energy cost is up to 3460 BTU. The treated rotor will last about 3x the life of the untreated rotor.

The nitrogen used in cryogenic processing does not pollute the atmosphere. It was taken from the atmosphere in the air separation process used to liquefy it, so it is just being released back from where it came. The atmosphere is about 79% nitrogen to begin with.

This is much less energy usage than purchasing three additional brake rotors, even recycled.

Contact Us Today

Partner with us to cut this pollution source considerably and enhance the life of your brakes and rotors. If you want to learn more about cryogenically treated brake rotors and how they can lengthen the life of vehicle parts, save you money, and protect the environment, reach out to us today.