Marine Cryogenic Treatment

Racing Boat Propeller

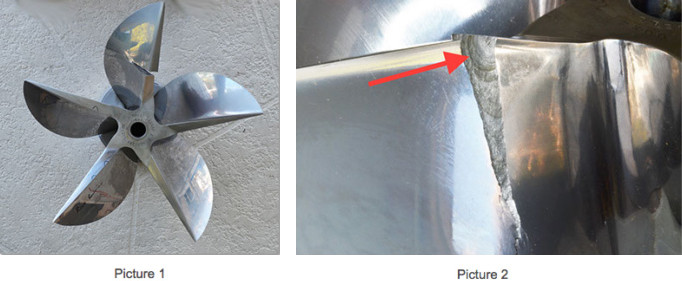

Racing puts unbelievable stresses on mechanical components. A quick look at this boat propeller will attest to that. It is rated at 1500 horsepower. The crack is huge, and luckily it stopped short of breaking the tip off.

This prop was on a racing boat owned by four-time offshore champion Rick Bowling, who runs twin Mercury Marine motors rated at 1350HP. It is made of a magnetic stainless steel described by Mercury Racing as a proprietary alloy. The prop costs over $5000.

Failed prop off the boat Gone Again

The crack (Picture 2) shows “beachmarks” (Indicated by the red arrow), which distinctly identifies it as a fatigue related crack. Most likely, the prop received some damage from striking debris in the water. That damage caused a stress concentration. Other blades show damage nicks at about the same area of the blade. These are indicated by black marks on the blades. There may also have been a discontinuity or an inclusion in the casting, which we are looking into.

The failure of the prop could have been worse. Had the blade separated on the up stroke it could have been thrown a heavy piece of metal at a considerable speed for a considerable distance. It would have made the propeller extremely out of balance which could have had destructive consequences to the drive system on the boat.

Cryogenic boat propeller treatment of the replacement through a process known as Deep Cryogenic Treatment (DCT) has dramatically improved the durability of the part greatly increasing its length of service life. The treated prop has three times the running hours on it of all previous props used. As of January 6, 2016, the treated replacement prop is still running strong. We will publish the total hours after the prop is out of service.

Don’t Get Left High And Dry

Whether you’re racing boats, ferrying cargo, or just want your fishing trips to last a little longer, giving your boat propeller a cryogenic treatment can keep you moving longer. Make the choice to protect your equipment. Contact us today and we can put together the right cryogenic treatment plan for you.