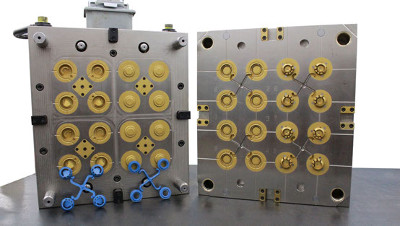

Plastic Molds

The plastic molding industry is extremely competitive, and Controlled Thermal Processing can help you get ahead. With whisker-thin margins, you can’t afford to submit to downtime and delays while you replace worn components, seized pins or have eroded gates or cavities fixed.

Deep cryogenic treatment of plastic molds, whether they be steel or other metallic molds throughout your system, can help minimize many of the issues you encounter during plastic molding processes.

How it Works

Deep cryogenically treated metal parts are beneficial to every part of the plastic molding processes. For example:

- Deep cryogenically treated metal is more resistant to abrasive materials such as glass and other wear producing additives. This leads to significant reduction in cavity wear, runner wear, and gate wear. Extrusion screws and extrusion dies also respond very well.

- Deep cryogenically treated metal has more consistent hardness making it easier to polish. This saves time and money in producing and maintaining molds.

- Deep cryogenically treated metal is more stable. Changes in size due to the conversion of retained austenite or due to release of residual stresses are minimized, reducing quality problems.

- Deep cryogenically treated ejector pins are more stable in size and shape. This has solved many problems where the pins stick or gall.

- Deep cryogenically treated of extruder screws and barrels extends their life considerably.

- Deep cryogenically treated sifter screens exhibit extended life over coated screens.

Many of our customers typically see two to three times the life on their molds, pins, and other parts.

Further Reading

Uses of Cryogenic Processing in the Thermoset Molding Industry

Click to see the whole article

Diekman, Frederick J.

Thermosets 2000 Conference

March 24, 2007, pp. 31-47

Contact Us Today

Controlled Thermal Processing is the leading industry expert on treating metal and steel parts involved in the plastic molding industry. We’ve worked with many companies who have seen huge improvements in their efficiency and creation processes. Reach out to us today to learn more about how we can help you save time and money.