Defining Cryogenic

- April 3, 2017

- Controlled Thermal Processing

- Cryogenic Treatment

Cryogenic Treatment

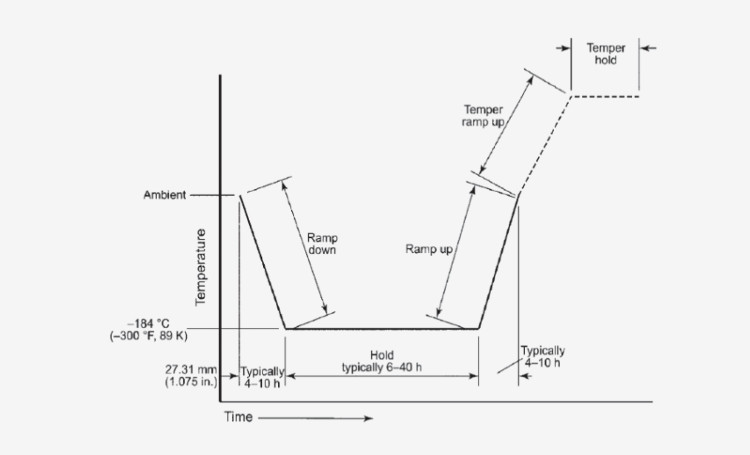

Figure 1: Typical Cryogenic Treatment Cooling Curve. Image: Republished with permission of ASM International, from ASM Handbook, Vol 4A, F. Diekman, “Cold & Cryogenic Treatment of Steel,” 2013; permission conveyed through Copyright Clearance Center, Inc.

Cryogenic treatment is the process of cooling materials to cryogenic temperatures temporarily to improve their material properties at room temperature. This is distinct from cooling materials down to cryogenic temperatures to take advantage of phenomena such as superconductivity that only occur at cryogenic temperatures. Cryogenic treatment, sometimes also referred to as deep cryogenic treatment, is best thought of as an additional process to other material processing steps such as heat treatment, quenching and cold work.

Depending on both the process applied and the material used, a number of material properties may be improved, including hardness, wear resistance (thus increasing lifetime), fatigue life and electrical conductivity:

As an example, Barron (1982) described an increase of wear resistance of tool steel treated down to -321F and can be attributed to the cause to a more complete transition from the austenite phase to the harder martensite phase.

While steel was one of the first materials to undergo cryogenic treatment—and the use of this technique to increase the lifetime of machine tools is one of its major applications—cryogenic treatment has been applied to a wide range of materials including Aluminum, brass, titanium, nickel alloys, Titanium, some plastics and even carbon nanotubes.

Cryogenic treatment generally occurs at roughly-321F (liquid nitrogen temperatures). Figure 1 shows a typical time versus temperature curve for cryogenic treatment. Some processes use dry ice temperatures (-120F) Which, while above the nominal -250F limit of cryogenics, are also sometimes referred to as cryogenic treatment.

Cryogenic treatment is a very active area of research that has produced many reproducible and industrially useful results. However, cryogenic treatment is not a remedy for all things and not all claims can be scientifically verified. Care must be taken in interpreting results in this area. Towards that end, the Cryogenic Society of America has established the Cryogenic Treatment Database (http://www.cryogenictreatmentdatabase.org).

This database, updated quarterly, contains articles and scientific papers that have been vetted by an impartial committee of experts.

A related topic is cryogenic machining: Here the material is cooled to cryogenic temperatures during the machining process. This is done to optimize the machining or to optimize the final machined piece, for example in terms of its surface finish, porosity or hardness. Again, as in the case of cryogenic treatment, the resulting material is typically used at room temperature.

A detailed introduction to cryogenic treatment is given in “Cold & Cryogenic Treatment of Steel” by our own F. Diekman, ASM Handbook, Vol. 4A (2013).